Elastic Binder: AXRO FQC2

Elastic Binder: AXRO FQC2

Elastic Binder: AXRO FQC2

Elastic Binder: AXRO FQC2

Our best selling Elastic binder

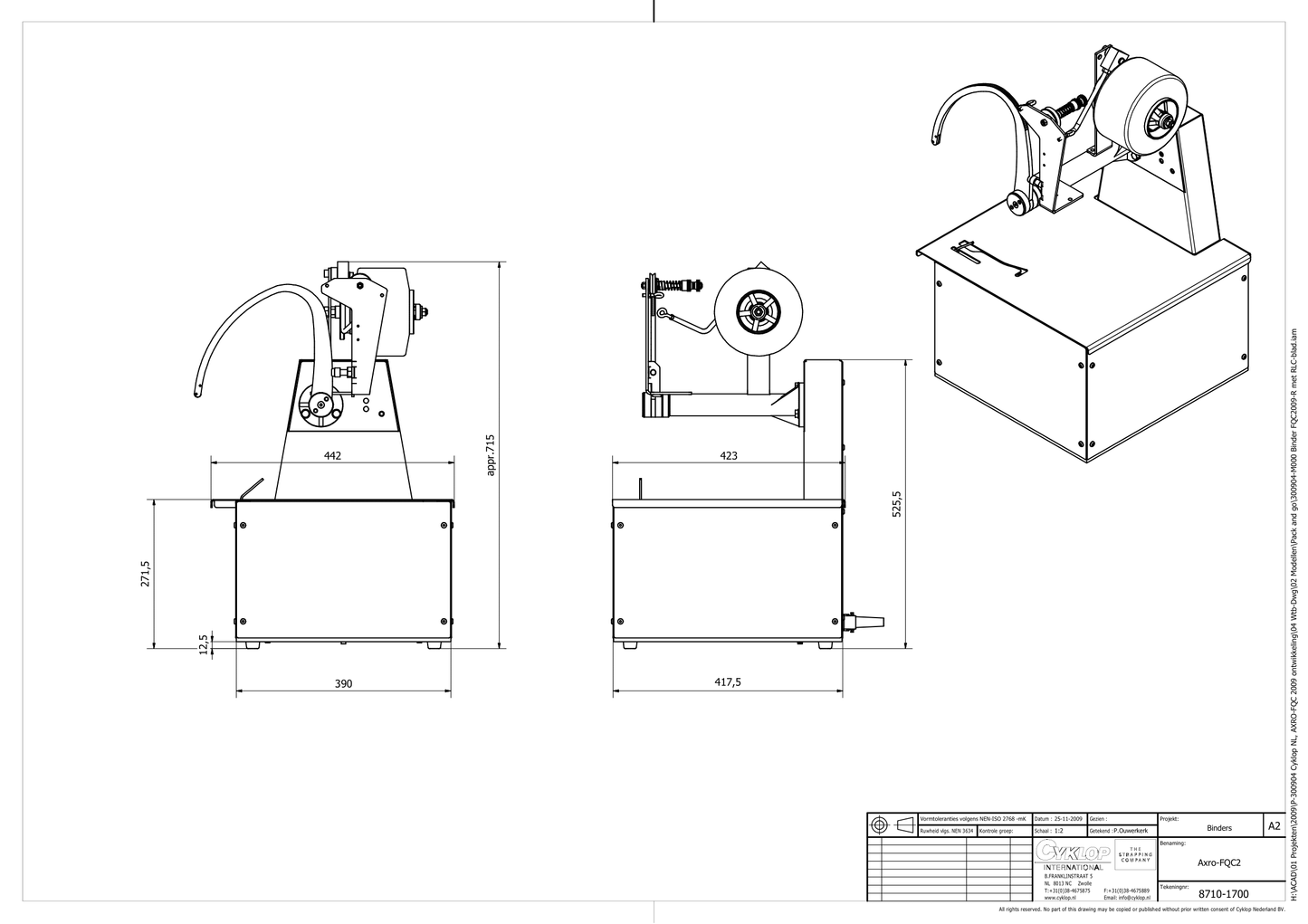

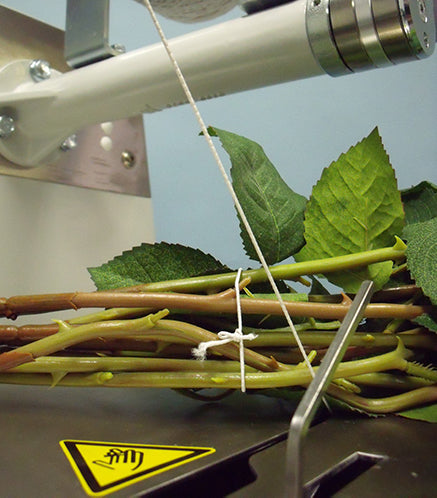

The Axro FQC2 efficiently bundles products like flowers, cables, and small boxes using an elastic cord. It takes a section from a roll of elastic, wraps it around the product with preset tension, and the patented Axro knotter head automatically ties the ends. The machine is ready for the next cycle immediately after. This high-speed solution can produce thousands of bundles per hour, making it ideal for high-output industries such as flowers, cables, and pharmaceuticals. Originating in the Netherlands' flower industry, it has proven valuable across various sectors by replacing costly and hazardous alternatives like tie wraps, increasing output, reducing packaging costs, and improving worker safety.

- For elastic cord Cylastic PE, Cylastic PCs 1300, Cylastic 3K

- Can be integrated into automatic machine lines

- Extremely easy operation

- Robust, capable of continuous operation

- Minimal maintenance

- Low noise

- Up to 100 cycles / minute

- Resistant to dirt

-

Increased Efficiency Through Automation: Automating the bundling process significantly reduces the time needed to bundle products, allowing more products to be bundled per day compared to manual bundling.

-

Integration with Automatic Machine Lines: The machine can be seamlessly integrated into existing automatic lines, enhancing operational efficiency.

-

Ease of Operation: The bundling process is extremely simple, requiring minimal effort and making it easy for anyone to use the machine quickly and professionally, despite level of experience and training.

-

Versatility in Bundling: The machine can handle both soft and hard products, ranging from flowers and vegetables to cables and cords, making it a flexible solution for various industries.

-

Replacement of Traditional Fasteners: It offers a safer and more cost-effective alternative to heavy, sharp fasteners like tie wraps and twist wraps.

Brochures & Download Materials

Service Videos

Product Videos

More Information

Features

- Advanced Knotting System (KRS): The knotter release system minimizes product damage by reducing tension during the bundling process, especially for delicate items.

- Compact and Noise-Reducing Design: Its lightweight construction and aluminum base plate reduce operational noise, creating a quieter working environment for employees.

- Feed-in mechanism

The AXRO-FQC2 is fitted with an updated “feed-in” mechanism whereby products are still bound properly even in the event of premature bind timing.So this means that despite an early feed in, the machine still makes a good bundling.

- Programmable Frequency controller

Allows to the tailor the bundling and knotting process to the exact needs of our customers. For example delayed start, extra torque or specific safety requirements.

- High-Speed and Durability:

Capable of up to 100 cycles per minute, the machine is designed for continuous operation, offering robust performance with minimal maintenance needs.

- Easy maintenance,

Most common service jobs and issues can be done and solved by customer. Easy access to machine.

Optional Components

- Vertical or Upside down construction

In dirty environments, dirt will not fall into the machine

- I-O connector for PLC Communication

- String-end Dectection

Signalling string end so that replacing coil can happen quickly

- 4-Wheel Support Frame

- Timer Function for delayed binding moment

- Selector swith for 1 or two bundling moments

- Left or Right version

Sometimes needed in automated lines - Startswitch: topswithc, mushroom, foot pedal, photocell

- Jumbo Coil

Higer uptime due to less coil changes

- Start interupter

Safety feature to protect operators