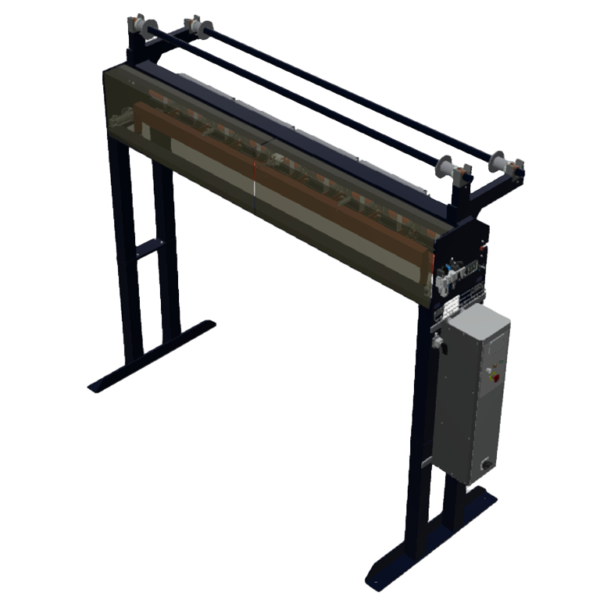

An electropneumatic and automatic packaging dispenser for up to 4 rolls of packaging plastic for efficient packaging of timber packages.

The Goliat automatic packaging dispenser, available in versions for plastic widths of up to 1300 mm, 2500 mm, 3400 mm, and 3700 mm, is primarily used in the timber industry. It is intended for covering timber packages on the top, on the long sides, and after folding and stapling, also on the ends. The plastic is designed to protect the timber against, for example, rain, snow, and dirt. The covering plastic that is rolled out has a variety of properties; in addition to width and thickness, it can be folded, equipped with anti-slip, colored, printed, and made from varying amounts of recycled PCR material.

The machine consists of a portal with dual roll holders and a feeding mechanism that feeds out the covering plastic synchronized with the package's transport through the machine. When the package has passed through the machine, the plastic is length-cut to the intended length with a cutting mechanism mounted under the feeding mechanism. The output speed can be adjusted up to 38.5 meters per minute via a frequency converter. One roll holder is used in operation, and the other is preloaded with a new roll. The quick actions to thread the spare roll through the feeding mechanism ensure a short roll change time and thus the highest possible availability.

The Goliat packaging dispenser is also built in a double version, where it is equipped with four roll holders and dual feeding mechanisms and cutters. With the double version, two types of plastic can be alternated automatically via the machine's interface, providing a very rational use.

In the standard version, the packaging dispenser is floor-mounted. If desired, it can also be delivered in a ceiling-mounted, mezzanine-mounted, or floor-mounted on a lift version.

Examples of common options for this machine are antistatic strips and a safety hatch, for enhanced personal safety in the work area.

- Suitable for the timber industry

- Can be delivered in single or double versions

- Automatic dispensing and cutting of top covering

Please feel free to study the machine using our 3D function below.

Cyklop

26480